Product

2400 high-speed cardboard box production line

The carton forming speed is fast. Suction and paper feeding are accurate.

Classification:

Keywords:

2400 high-speed cardboard box production line

Product description

Acceptance criteria: positive and negative mouth 2.5mm, scissor edge 1mm.

Mechanical parameters: maximum speed 300m/minute, roll out packs 20 packs/1 minute.

Equipment features:

- The carton forming speed is fast.

- Suction and paper feeding are accurate.

- The size of the mouth is well controlled, and the waste is adhered to.

- Secondary deviation correction to completely eliminate the scissor edge.

- Count accurately.

- The beating part makes the carton molded well.

- The pile is accurate and neat.

- Automatic glue supply, uniform glue application, saving glue amount, and at the same time with glue shortage alarm function.

- Digital remote control, accurate, convenient and fast.

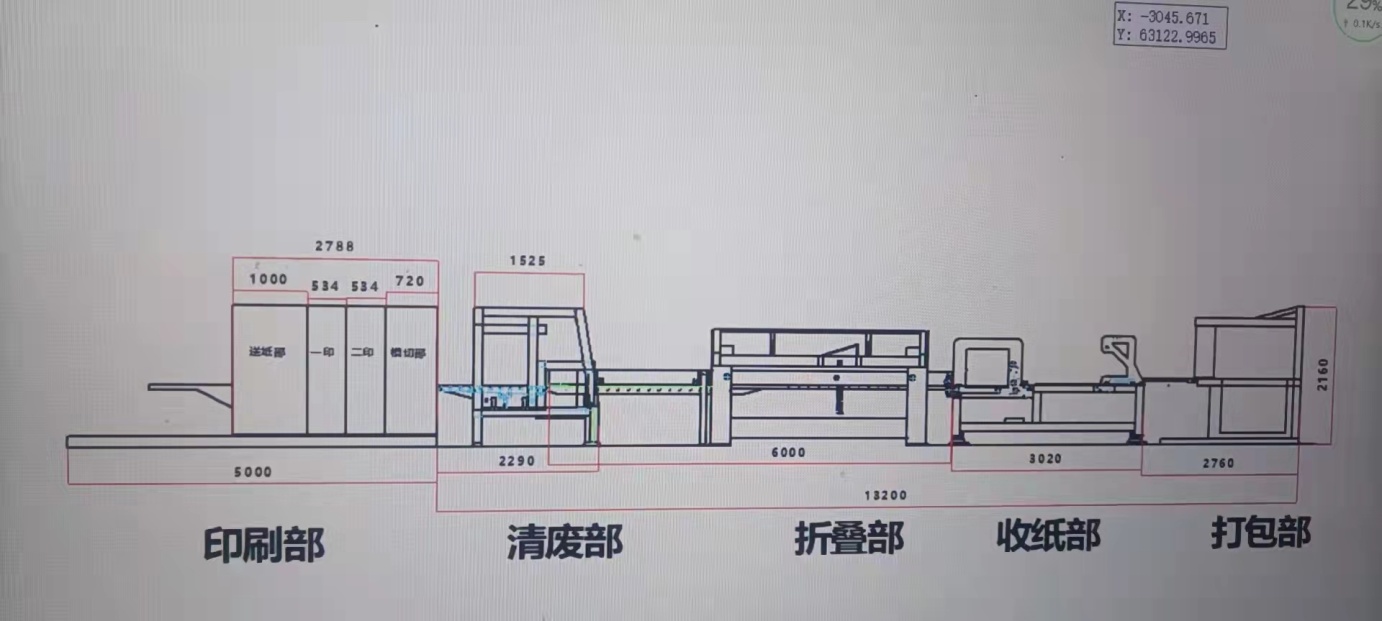

First, the introduction of the whole machine

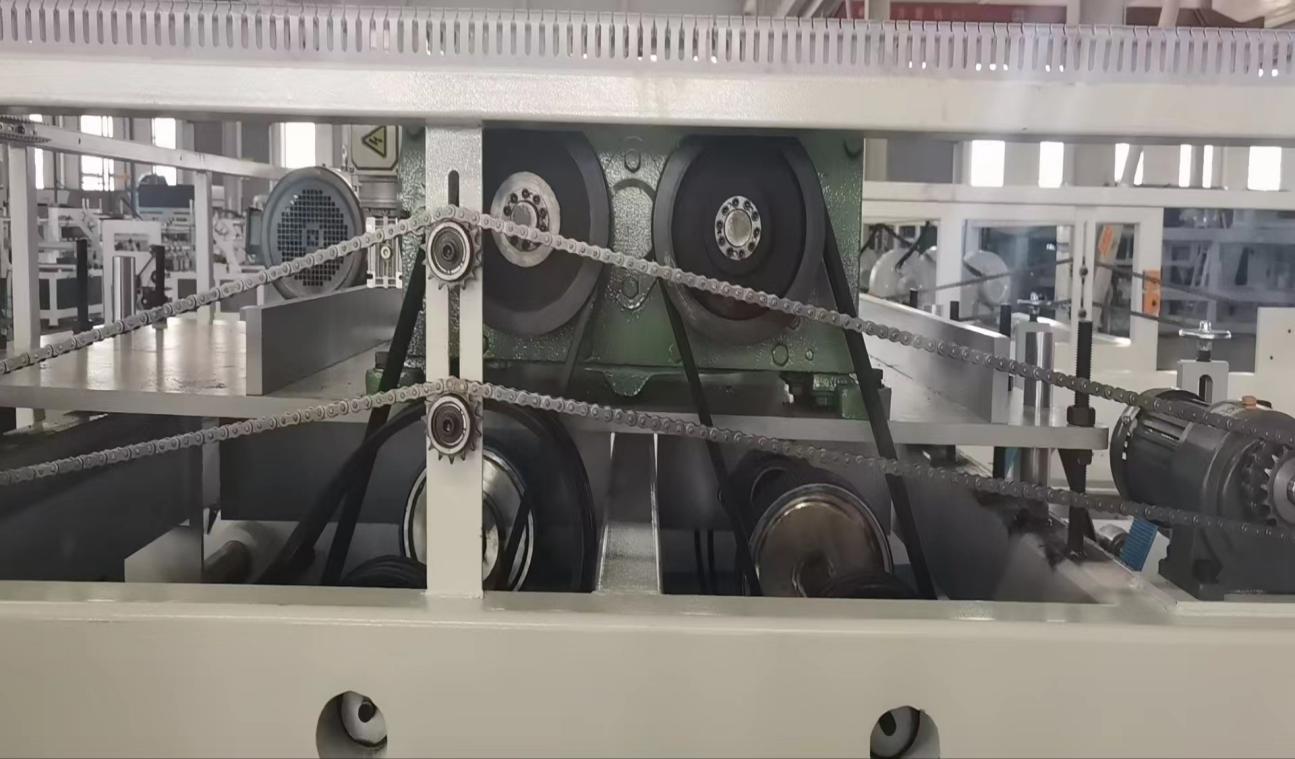

1. The front is connected with the die-cutting part of the printing machine, and the back is connected with the folding part of the linkage line sticky box, all the paper-walking belts can be moved separately, and the paper-walking belts are equipped with paper rollers, fans, and brushes to clean up the waste paper waste to the greatest extent. Guide wheel device, upper and lower belt clamping and transmission. Electric left and right walking, easy to adjust the size and size.

2. Rubbering wheel: made of stainless steel, more durable and corrosion-resistant. The gluing bucket uses a linear guide rail, which is more convenient and accurate to adjust the position.

3. Folding part: The main function is to fold the carton downward, and fold the cardboard into a standardized box through the correction board for the second correction line.

4. Forming and cleaning, if the waste removal part and the folding part are not cleaned up, the waste paper scraps will be cleaned up for the second time.

5. Shoot the whole part: beat the number of points, and launch it with an accurate number by counting the optical eyes, counting and correcting.

6、Output section: After being pushed out, the above paper holder smoothly presses the output.

8、The left and right folds of the belt each have a belt differential function.

Mechanical configuration of packaging department:

(1) Taizhou Haoli reducer

(2) Yadeke cylinder, solenoid valve

(3) Guangdong Dafu Power Transmission Shaft

(4) Bearing Harbin

Electrical configuration:

(1) Panasonic PLC

(2) SIMEN contactor

(3) Schneider button

(4) Switching power supply Taiwan Mingwei

(5) Optoelectronic switch Beifuning

(6) Relay Omron

(7) Human computer interface Kunlun communication status

8. Control panel; Adopting PLC control, with functions such as zeroing and memory. (PLC combined with touch screen control can be selected)

9. Electrical configuration:

Main control computer PLC: Panasonic

Touch screen: Kunlun Tongshou

Switching power supply: Mean Well

Inverter: Delta

Intermediate Relay: Omron

Circuit breaker: Siemens

Contactor: Siemens

Photoelectric switch: Hugong Group

Terminal: CHINT

10. The controller panel of each action of the machine controls the left and right movements, the rise and fall of the paper pressing frame, etc.

Second, the working principle of the machine:

When the cardboard is glued, folded, corrected, stacked and conveyed to the baler, the baler is controlled by the PLC to operate。

Parts of the machine are optional:

1. Automatic glue supply, circulating glue, never broken glue, no need to manually add glue, saving time and effort. Suitable for all kinds of glues.

2. Stainless steel gluing wheel, corrosion resistance, wear resistance, uniform gluing, glue saving, glue consumption is about one-third of the amount of manual gluing.

3. The folding part is equipped with an adjustable multi-channel crimping wheel, which makes the carton folding smoother and the bonding more beautiful and accurate.

4. The carton accumulation correction of the counting department, the stacking and output are safe and stable, accurate and error-free, digital control, simple operation, and can be input without stopping.

3. Machine parameters

(1). The maximum speed of the machine is 320 m/min

(2). Maximum number of packs: 20 packs

Maximum cardboard size (including lid): 2600mm*1200mm

Minimum cardboard size (including lid): 600mm*240mm

Maximum stack height: 350mm Minimum stack height: 80mm

Maximum quantity per pack: 50 pcs Minimum quantity per pack: 10 pcs

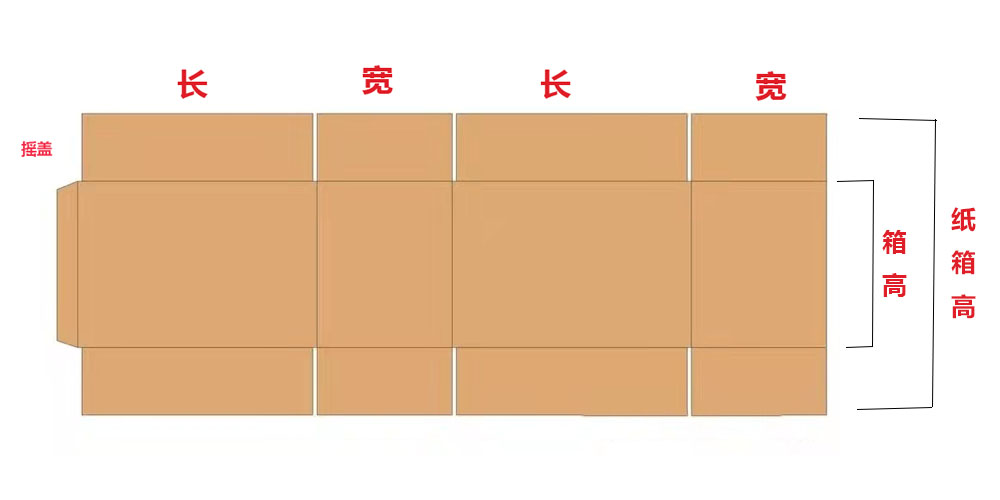

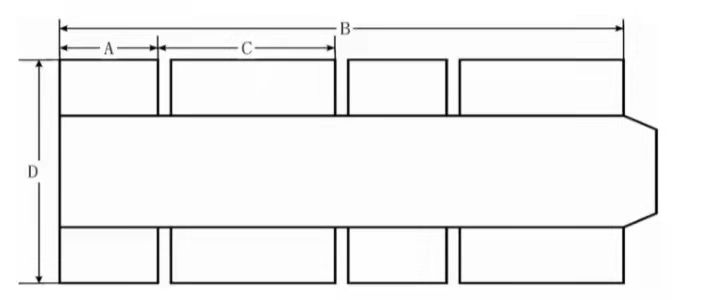

Schematic diagram of processing cartons in the gluing department:

If the specifications are special, the machine can be designed and manufactured according to the requirements.

|

Model |

Type 2600 |

|

Size A (mm). |

80–660 |

|

Size B (mm). |

600–2600 |

|

尺寸C(mm) |

165–660 |

|

尺寸D(mm) |

240–1200 |

|

Installation area (mm). |

10.5-3.5 US |

|

电机功率(KW) |

8kw |

|

整机重量(T) |

5.5T |

This machine can process 2-8mm three-layer and five layer corrugated cardboard

This machine can process 2-8mm three-layer and five layer corrugated cardboard

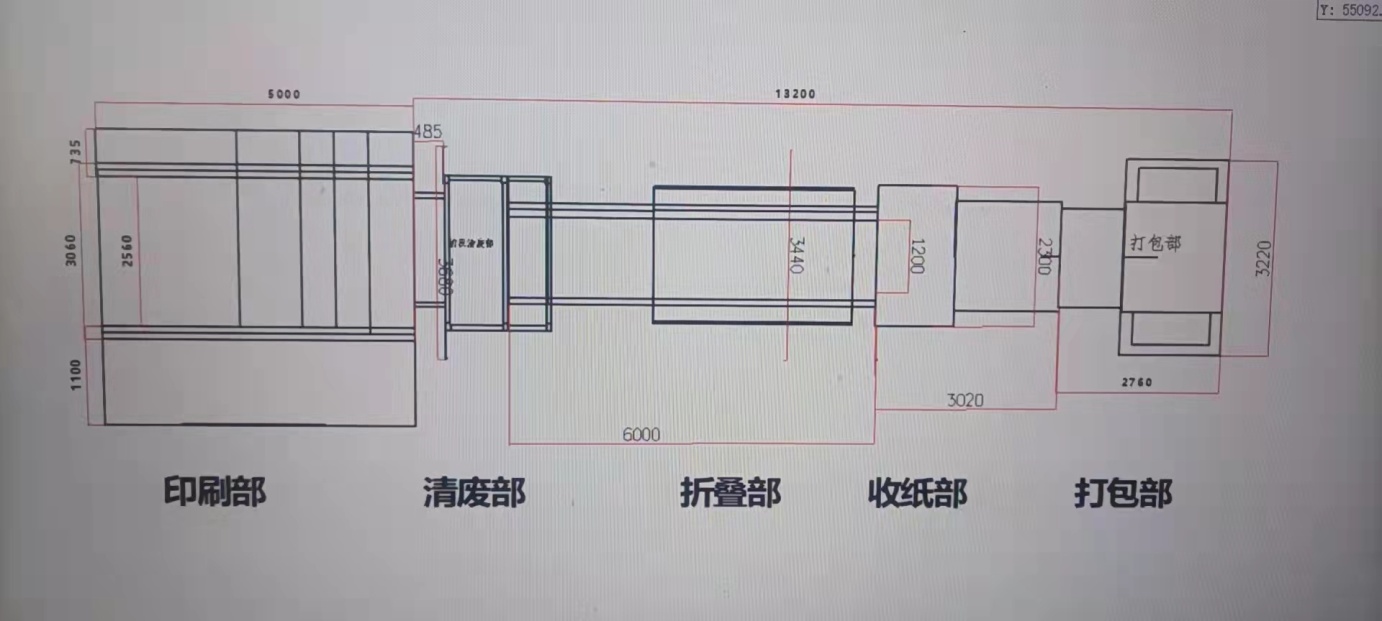

Fourth, the high-speed linkage line maintenance and refueling diagram:

Where there is a mark in the picture, pay attention to the regular refueling and maintenance 'once every half month'to ensure the normal operation of the machine and the service life of the machine is longer.

5. High-speed linkage production line foundation display diagram:

Annex I:

Buyer's Own Items:

1. The machine arrives and prepares the forklift, five to eight tons, long forks.

2. Prepare relevant venues.

3. Prepare the main power cord and gas.

4. Safety-related personnel help.

5. Prepare the cardboard and test the machine at any time.

Annex II:

Safe Operation:

1. Before going to work, you must wear work clothes and work shoes, buckle a button and cuffs, and do not contain items that are easy to fall in your pocket.

2. After the crew arrives at the post, check that there are no personnel and sundries within the operating range of the equipment. The protective cover on the equipment must be intact and not loose.

3. Before the equipment starts, the alarm should be ringed, and the operation can be started only after the equipment is confirmed that there are no personnel in the operating range.

4. During the operation of the equipment, it is strictly forbidden to touch all the working surfaces with your hands, and it is not allowed to carry out maintenance and wiping work. It is not allowed to cross the running part.

5. The crew should strictly abide by their posts according to the division of labor, prohibit them from working in tandem and leaving their posts without permission, and always pay attention to the operation of the equipment.

4. During the operation of the equipment, it is strictly forbidden to touch all the working surfaces with your hands, and it is not allowed to carry out maintenance and wiping work. It is not allowed to cross the running part.

5. The crew should strictly abide by their posts according to the division of labor, prohibit them from working in tandem and leaving their posts without permission, and always pay attention to the operation of the equipment.

If an abnormality is found, it will be shut down in time.

- No one is allowed to play around the equipment and make loud noises while working.

- During the work process, the work site should be kept clean and unobstructed. Make sure there is no clutter around the device. Tools and parts should be placed in the designated position.

8. The operator of this machine should be familiar with the function and position of the main buttons of the equipment, and anyone can press the emergency stop switch if there is an accident.

6. Warranty period:

The whole machine is guaranteed for one year, and the supplier is responsible for the repair and replacement of the design or parts quality problems during the warranty period, and all the costs of machine failure caused by improper operation or weather and natural disasters are borne by the buyer.

Dongguang Yixin Carton Equipment Manufacturing Co., Ltd(Attachment) Details of Machine Accessories

- 2 climbing belts: 3920*90 (steel buckle), steel wire 0.5 meters

- 2 times crimping small belt: 2460*50, 1620*50.

- Eyes: 2

- A set of inner wrenches, a 12-inch movable wrench, a dead wrench 17-19, 16-18 each.

- Spring plate pressure wheels: 10 pcs

- 1 solenoid valve

- 4 small dragon boats

- Five-core wire 30 meters

- Four-core wire 30 meters

- Housing fixing screw: 10# inside8# Inner square, flat pad,A number of elastic pads and nuts

- Waste cleaning plate round belt, 650 triangle belt type A

- Adjustable pneumatic joints: 10 pcs 8 pcs (2 each) 10 to 8 tees (210 straight-through, 8 (2 names), 10 tees, two

- Rubber bucket sealing tape: 2 pieces

- Rear platen rollers: 2 pcs

Online inquiry

Contact

Email:green@yxzxsb.cn

Address:Cangzhou city, Hebei Province, Dongguang economic development zone packaging and machinery and equipment manufacturing zone A

Copyright © 2023 Dongguang yixin carton equipment manufacture co., ltd All Rights Reserved. Powered by 300.cn SEO Business License