Product

2600 automatic box gluing machine

Dongguang County Yixin Carton Equipment Manufacturing Co., Ltd. is a professional company engaged in the design and manufacturing of carton machinery. It is a well-known enterprise in the production base of carton machinery in the north - Dongguang Carton Machinery. Since its establishment for many years, it has always been in a leading position in research, development, and production.

Classification:

Keywords:

2600 automatic box gluing machine

Product description

main features:

1. This machine adopts a grouping structure, and each unit adopts an independent motor to provide power, achieving shaftless operation, stable operation, and simple maintenance.

2. The motor of this machine is controlled by a frequency converter, which ensures more stable operation and saves power

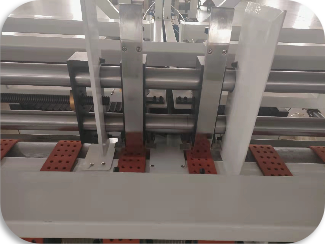

3. Paper output adopts multiple thickened and widened belts equipped with air suction devices to ensure continuous, accurate, and automatic paper feeding

4. The transmission part adopts a reinforced ultra wide belt for up and down main transmission, which eliminates the need to disassemble the shaft and quickly replace the belt

5. Adopt man-machine, PLC operating system and remote control operating system, equipped with photoelectric counting, quantitative counting, and equipped with automatic paper kicking device

6. This machine is equipped with an automatic aligning device to correct the skewed products generated during the carton pasting process, ensuring product quality

● Carton molding speed is fast ● Accurate counting ● Accurate air suction and paper feeding ● The beating section shapes the carton well

● Secondary indentation for more accurate origami ● Accurate and tidy stacking ● Good control of large and small openings to reduce waste

● Automatic glue supply, uniform glue application, and saving glue amount ● Secondary correction to completely eliminate the scissors

● Digital remote control, accurate, convenient and fast

1、Paper supply department:

(1)Adopt belt leading edge suction and paper feeding method, accurate and reliable.

(2)Using a high-end electromagnetic clutch and electromagnetic brake system, the paper feeding section can be independently controlled, and the operation is simple and reliable.

(3)Adjustable paper pressing wheel, suitable for paperboard thickness of 2-8mm.

(4)Linkage with folding part, variable frequency speed regulation, paper feeding speed 130m/min.

(5)The front baffle and paper feeding belt of the paper feeding section are adjustable from left to right.

2.Inclined plate shutdown function:Prevent the cardboard from coming out obliquely, and stopping the main machine after feeding the paper after the inclined plate comes out can effectively avoid excessive waste of cardboard.

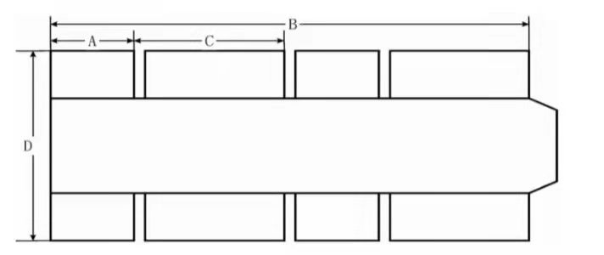

(1)First fold the cardboard to be glued, align the bonding area with the center, and place it on the paper supply belt. After unfolding, turn the cardboard aside to stick the right board to the right side of the cardboard, and also lean the left board over.

(2)Use the left and right movement switch to move the left and right indentation wheels to the center of the left and right indentation grooves of the cardboard.

(3)Move the paper feeding belt and place it in place to evenly distribute the belt.

(4)Move the left and right front fenders over the appropriate belts on the left and right sides. Be careful not to place them in the wire pressing groove to prevent deviation.

(5)The gap between the front bezel and the paperboard is generally higher than one-third of the thickness of the paperboard.

(6)Adjust the angle of the paper feed rack without changing it. Adjust the distance between the front and back to hang the cardboard at the lower end of the ramp to minimize the angle between the belt and the cardboard.

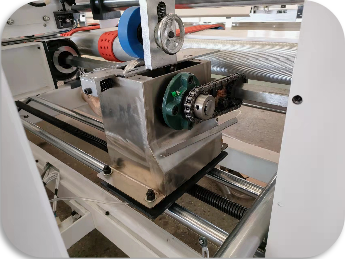

3. Positioning of gluing wheel:

(1)Adjust the gap between the small pressure wheel on the gluing device and the gluing device to the thickness of the cardboard.

(2)Operate the machine at a slow speed, use the paper supply switch to pull out a piece of cardboard and stop before the gluing wheel. At the same time, move the gluing wheel to the appropriate position.

(3)After gluing the first piece of cardboard, observe the gluing position and amount, and adjust the gluing amount with fine adjustment.

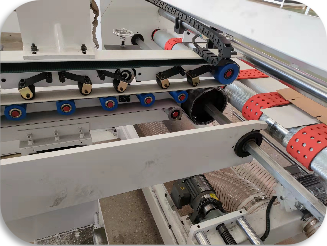

4. Folding part:It is the main part of paper feeding and folding molding, equipped with infrared ray alignment, pre pressing and secondary pressing, and correction line board.

(1)The main motor adopts frequency conversion speed regulation, with no noise in the system and flexible and stable speed regulation.

(2)Imported high friction belt is used to transport cardboard and automatically fold it.

(3)Use stainless steel wheels to apply glue, which is uniform, trouble-free, and saves glue.

(4)The folding part is equipped with a cardboard correction device and an indentation correction device.

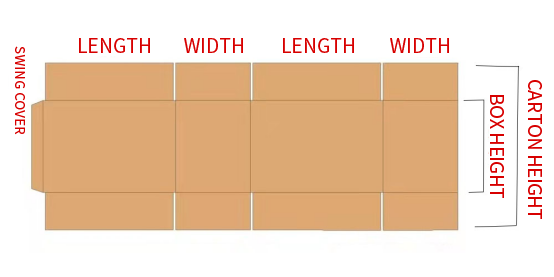

(5)Cardboard specification: minimum 540 * 90, maximum 3000 * 1300

(6)Folding speed 130m/min

5. Imported cylinder

The gas pressure is set using a regulator. Generally, the gas pressure is set at about 5 air pressures, with less than 4 cylinders moving slowly, and more than 5 cylinders moving too fast, which can cause adverse factors to the box gluing machine and should be avoided.

6. Counting and stacking section:

(1)Adopt digital control, simple operation, reliable action, can input data without shutdown, automatic counting, and accurate output.

(2)Cartons are transported by belt, stacked neatly, with a stacking speed of 120m/min.

(3)With deviation correction function, the deviation can be adjusted.

(4)The counting and pushing out adopt pneumatic mode, with reliable, accurate and fast action.

7. Counting and stacking output unit:

(1)After adjusting the paper supply and folding, first place a stacked cardboard box at the counting and stacking section, that is, between the flap and the trolley baffle, and move the trolley until the baffle and the flap are strong.

(2)Set the base number; Set the base number and the desired number of sheets based on the size and thickness of the carton. After setting the base number, it should be higher than the height of the baffle plate, so that it can be pushed normally.

(3)Set the number of sheets counted: The number of sheets set depends on the thickness and size of the carton. The setting range is generally 8-20 sheets.

(4)After setting the startup, use the slow speed to wait for the first count to push out and then stop the machine. Adjust the height of the upper conveyor belt device so that the belt properly presses the carton through.

(5)The sun wheel should be placed between the front and rear of the adhesive part of the carton, and the pressure should not be too high, just lightly.

8. PLC computer controller:Adopt man-machine, PLC operating system and remote control operating system, equipped with photoelectric counting, quantitative counting, and equipped with automatic paper kicking device.

Machine parameters:

Maximum machine speed: 320 meters/min

Maximum number of packages launched: 20

Maximum cardboard size: 3000mm * 1300mm

Minimum cardboard size: 540mm * 90mm

Maximum width of paperboard (including swing cover): 1100mm

Minimum width of paperboard (including swing cover): 150mm

When the normal carton is 1150mm long, the width cannot exceed 350mm

The length of the special box is 1200mm, but it cannot exceed 1200mm, and the width cannot exceed 380mm

Maximum stacking height: 350mm

Minimum stacking height: 80mm

Maximum quantity per package: 50

Minimum quantity per package: 10

Belt: Siegling (Sino German joint venture)

Online inquiry

Contact

Email:green@yxzxsb.cn

Address:Cangzhou city, Hebei Province, Dongguang economic development zone packaging and machinery and equipment manufacturing zone A

Copyright © 2023 Dongguang yixin carton equipment manufacture co., ltd All Rights Reserved. Powered by 300.cn SEO Business License