Product

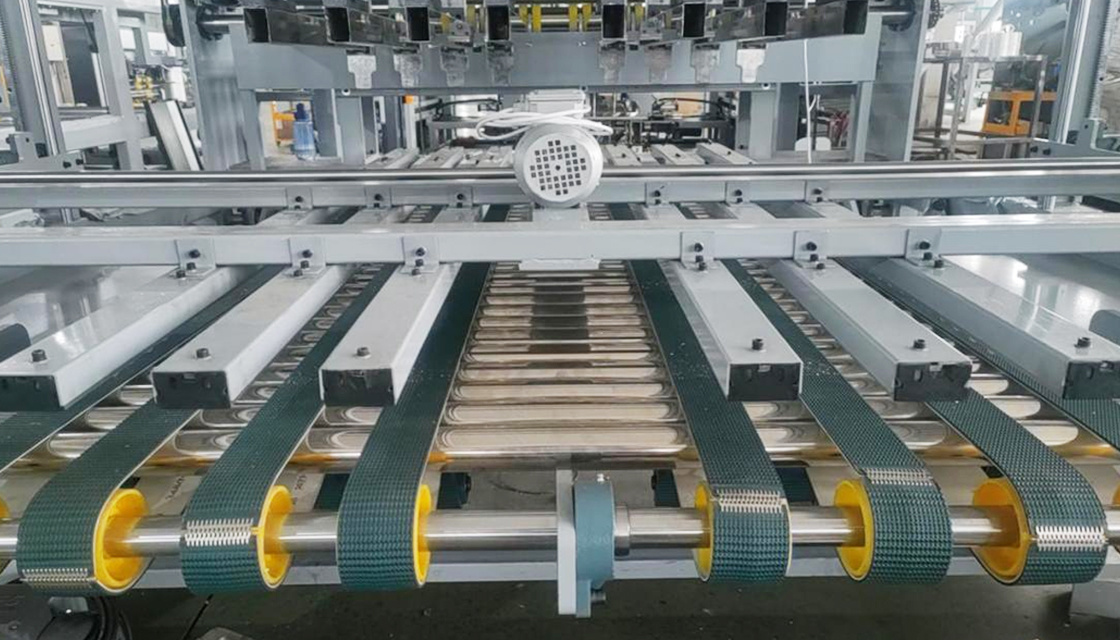

1224 full computer high-speed four-color printing slotting die cutting adhesive nail bundling linkage line

Acceptance criteria: positive and negative edges 2mm, scissors edge 1mm. Mechanical parameters: maximum speed 350 meters/minute, number of packages launched 20 bags/minute.

Classification:

Keywords:

1224 full computer high-speed four-color printing slotting die cutting adhesive nail bundling linkage line

Product description

Key features:

The latest industrial appearance design, all gear covers of the whole machine are made of high-quality stainless steel, beautiful and durable.

The whole machine is driven in a unified manner, pneumatic interlocking, each unit is automatically or individually opened and closed, and the bell continues to ring the warning when walking, reminding the operator and ensuring the safety of personnel.

Each unit is equipped with an emergency stop switch to stop the movement of each unit internally. Ensure the safety of internal operators.

The maximum speed is 260 sheets/min, which effectively improves production efficiency.

All main transmission gears are made of special imported materials (20CrMnTi), carburizing and quenching, precision grinding, and durable;

The gear lubrication adopts an oil pump spray system.

All control appliances are made of international brands, stable and durable, the main control electrical box is equipped with industrial constant temperature air conditioning, and each branch electrical appliance is equipped with dustproof and heat dissipation devices to ensure stable and reliable control and operation performance.

The whole machine is equipped with automatic oil circuit balance system and automatic circulating lubrication system.

Introduction:

|

|

|

|

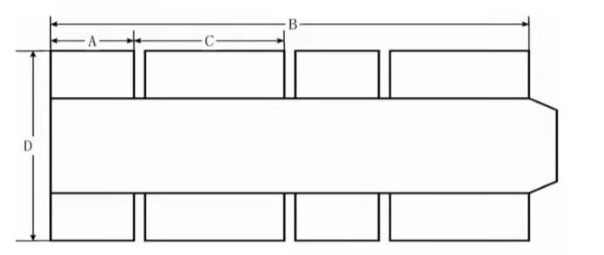

1. The front is connected with the die-cutting part of the printing machine, and the back is connected with the folding part of the linkage line sticky box, all the paper-walking belts can be moved separately, and the paper-walking belts are equipped with paper rollers, fans, and brushes to clean up the waste paper waste to the greatest extent. Guide wheel device, upper and lower belt clamping and transmission. Electric left and right walking, easy to adjust the size and size |

2. Rubbering wheel: made of stainless steel, more durable and corrosion-resistant. The gluing bucket uses a linear guide rail, which is more convenient and accurate to adjust the position. |

|

|

|

|

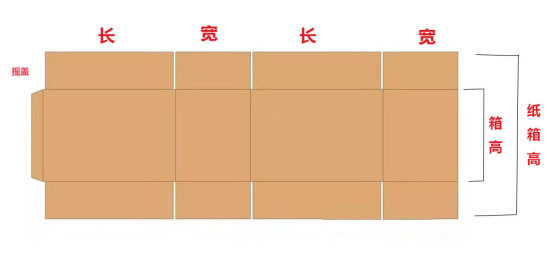

3. Folding part: The main function is to fold the carton downward, and fold the cardboard into a standardized box through the correction board for the second correction line. |

4. Nail head power: for servo motor, this machine adopts a swing head, and the nail head speed is 1000 nails/min. 1) Servo baffle, more sensitive response and faster speed. 2) This machine can nail single nails, double nails, and reinforcing nails at one time 3) This machine can be nailed to three layers, five layers of cartons (seven layers need to be declared in advance when ordering) 4), control panel; It is controlled by PLC and has zeroing |

|

|

|

| 5. a control panel; It adopts PLC control, with functions such as zero and memory. (Optional PLC combined with touch screen control) | 6. The controller panel of each action of the machine controls the left and right movements, the rise and fall of the paper pressing frame, etc. |

Machine maximum speed: 320m/min

, maximum number of packs: 20 packs

, maximum cardboard size: 700mm*500mm

, minimum cardboard size: 195mm*105mm,

nail box side microphone is not less than 240mm

, maximum stacking height: 350mm

, minimum stacking height:

Minimum Quantity Per Pack: 10 Belts

: West Green (Sino-German Joint Venture)

Online inquiry

Contact

Email:green@yxzxsb.cn

Address:Cangzhou city, Hebei Province, Dongguang economic development zone packaging and machinery and equipment manufacturing zone A

Copyright © 2023 Dongguang yixin carton equipment manufacture co., ltd All Rights Reserved. Powered by 300.cn SEO Business License