Product

2200 fully automatic adhesive nail integrated machine

Dongguang County Yixin Carton Equipment Manufacturing Co., Ltd. is a professional company engaged in the design and manufacturing of carton machinery. It is a well-known enterprise in the production base of carton machinery in the north - Dongguang Carton Machinery. Since its establishment for many years, it has always been in a leading position in research, development, and production.

Classification:

Keywords:

2200 fully automatic adhesive nail integrated machine

Product description

Machine composition and operating principle:

1. The automatic box gluing machine consists of three parts: a paper feeding and gluing section, a line pressing and folding section, and a correction and counting output section.

2. This machine is made of high-quality steel welded and meticulously processed and assembled.

3. Adopt belt type leading edge suction and paper feeding, accurate and fast.

4. Automatic glue supply, circulating glue, never breaking glue, no need to add glue manually, saving time and effort.

5. Stainless steel glue coating wheel is corrosion resistant, wear-resistant, evenly coated, and saves glue. The amount of glue used is about one-third of the amount of manual glue coating.

6. The folding section is equipped with an adjustable multi-channel pressing wheel set, which makes the folding of the carton smoother and the adhesion more beautiful and accurate.

7. The counting unit corrects the stacking of cartons, ensuring a safe and stable output, accuracy, and error free. Digital control ensures simple operation, and allows input without stopping the machine.

8. The machine is equipped with fault detection, which automatically stops working when the cardboard fails, reducing the waste of cardboard.

9. This machine can store 1000 orders, and can be adjusted automatically or manually. Transfer out orders are automatically adjusted, and changing orders only takes a few minutes. Reduced order change time and improved work efficiency.

10. This machine is designed with a box shaping function to ensure that there are no scissors when nailing the box, which is neat and not skewed.

Main technical indicators:

Head rotation speed: 420-1000 nails/min

Nailing speed: 90-260m/min

Nail box accuracy: 0.1mm

Nail box mode: single chip

Startup method: automatic detection of cardboard startup

Maximum power: 4.0kw

Power supply voltage: three-phase four-wire AC380V ± 10%, phase zero voltage AC220V ± 10%

Power wiring: multi-strand flexible copper wire with an area of more than 4 square meters

Ambient temperature: 0-40 ° C

Ambient humidity: below 10-90% RH (should be free of condensation)

Environmental vibration: acceleration below 5.9m/s2 (0.6G)

Protection structure: IP20 cabinet installation

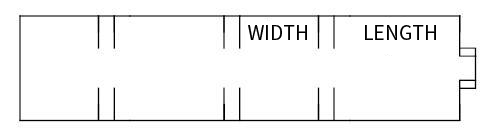

The maximum design speed of this machine is 150m/min, and the overall dimensions are 14m long, 3m wide, and 1.7m high.

This machine can process corrugated cardboard boxes with three or five layers (2-9mm).

The processing range is as follows: maximum 2200-1000 paperboard, minimum 420-125 paperboard

Carton length not greater than 880 and not less than 130

Carton width not greater than 880 and not less than 60

Carton height not less than 70 degrees but more than 1000 degrees

Online inquiry

Contact

Email:green@yxzxsb.cn

Address:Cangzhou city, Hebei Province, Dongguang economic development zone packaging and machinery and equipment manufacturing zone A

Copyright © 2023 Dongguang yixin carton equipment manufacture co., ltd All Rights Reserved. Powered by 300.cn SEO Business License